A comprehensive guide to quarry and sand and gravel operations, covering equipment, process design, automation, wear parts and service. Learn how to optimize your aggregates processing with Metso's global expertise and solutions.

More

The primary crusher reduces the size of boulders into smaller pieces and then it is conveyed to the secondary crusher (primary Impact crusher). The gravel is

More

2022年4月26日 The objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure development, while the objective in minerals...

More

Processing techniques basically involve crushing and screening in crushed stone aggregates while sand and gravel materials are processed using screening and washing methods. These

More

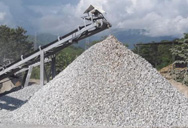

Aggregate crushing plant produce construction aggregates widely used for making concrete production. The aggregate process consists by progressive stages of crushing, screening, and washing.

More

In this processing process, remove the scrap iron in the aggregate. First-level Crushing Process. First, we usually apply a crushing machine, a mobile jaw crusher to crush the raw materials in the first level. First, the vibrating feeder

More

2024年2月27日 A detailed process to extract valuable and reusable recycled aggregate from waste concrete is presented in this chapter. Additional crushing stages and treatment

More

Crusher Plant Aggregate crushing operation is the process of dealing with and processing non-metallic mineral materials for the construction industry. Non-metallic mineral material will be first quarried and then conveyed to the

More

2018年11月1日 Learn more on how General Kinematics is leading the charge in the aggregate manufacturing process with expert service and equipment. Skip to main content. 815-455-3222. Top Menu. About. ... a plant will have a

More

Aggregate Production Process. Our Crushing Plant is now considered the most reliable plant in CALABARZON, specifically Batangas. The plant is located at Brgy. Lucsuhin, Calatagan, Batangas, Philippines. QUARRYING. This is an

More

2014年1月1日 A statement of the problem of crushing plant optimisation is formulated and a genetic evolutionary algorithm has been included in the software in order to facilitate the optimisation process.The ...

More

Aggregate Crushing. Most of the time, aggregate emerges from extraction as masses larger than the final product desired. Aggregate crushing is the process of breaking down the large pieces into smaller particles, using several types of heavy machinery, including: Jaw crushers; Impact crushers; Cone crushers; Aggregate Screening

More

2023年2月28日 Aggregate Crushing Plant; Limestone Crushing Plant; Granite Crushing Plant; Projects Menu Toggle. 500t/h Coal Gangue Mobile Crushing Plant; ... We will delve into each stage of the crushing process, discussing the types of crushers used, their working principles, common applications, and differences between them and other comminution ...

More

Influence of Natural Aggregate Crushing Process on Crushing Strength Index Andrzej Pacana 1, Dominika Siwiec 1, Lucia Bednarova 2, ... The design of a crushing plant by only

More

Non-metallic mineral material will be first quarried and then conveyed to the processing plant for further classification or further size reduction by the aggregate crushing plant. A crushing plant is a one-stop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing, and other similar operations.

More

2024年3月19日 Optimizing Aggregate Production with SBM's Crushing Plant: A Comprehensive Process Overview Navigating the intricacies of aggregate production demands a systematic approach, particularly in ...

More

2024年2月27日 Manual screening and sorting of waste concrete from C D debris is the first step of the recycling process. Subsequently, the waste concrete goes through different crushing processes to acquire desirable grading of recycled aggregate. Firstly, the large concrete blocks are broken into pieces using impact crusher and also done manually by hammer.

More

2023年6月2日 The process of an aggregate crushing plant involves multiple stages, including feeding, crushing, screening, and conveying. Here is a step-by-step description of the aggregate crushing plant and ...

More

Of course, according to different requirements, customers can adjust the size of their final products from this stone crushing plant. Process of Stone Crushing Plant; Clients will get the satisfactory products after objects being crushed for several times. Dust is generated during the working process while the dust control units are needed.

More

The screening process is just as important as the crushing itself. Screens are the hub of every rock processing plant. They are used to classify materials both in different stages of the crushing process and in final product separation. Designed as a non-welded frame with adjustable vibration features for different material types

More

2020年2月8日 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction). The CSS, as well as the

More

2021年8月25日 To make the decision based on the simulation model of equipment and process, referring to an aggregate crushing plant, there is a need to develop a calibration and maintenance routine for process simulation to derive useful and reliable results from the optimization function [7,8,9,10].

More

2021年7月27日 The aggregate crushing process was carried out for 4–8 mm and 10–14 mm fractions using cone crushers of the 1044 type. Aggregate crushing was carried out in a Los Angeles drum, in accordance with the requirements of EN 1097-2:2020. ... At the ZEK Ostrów plant, the aggregate was elongated, ellipsoid, partially rounded or flat.

More

2021年10月1日 This video will show you the complete process of crushing plant. Also shows that how stones are crushed in plant to get aggregate base course, stone dust etc...

More

Knowing about the main components, it is easy to have a better understanding of the aggregate crushing plant works. Check how the crusher plant works below. Working Process of The Crushing Plant in The Philippines. The working process of a crushing plant in the Philippines can be divided into six simple steps as follow:

More

2015年1月1日 Risks have important impact on aggregate crushing plant in terms of its primary objectives. The record of the aggregate crushing plant is not suitable in terms of managing up with risks in plant.

More

How to Run an Aggregate Crushing Plant? At the same time of economic development, the concrete industry is booming, aggregate sand takes an 80% proportion in all materials of concrete. Improving the productivity of aggregate processing plant, which on the sand aggregate manufacturing process put forward higher requirements.

More

2021年7月27日 The aggregate crushing process was carried out for 4–8 mm and 10–14 mm fractions using cone crushers of the 1044 type. ... The design of a crushing plant by only.

More