Alumina Liner. The alumina lining bricks are used as the lining in the ball mill of ceramic industry, insulator industry. Using this liner will effectively improve grinding efficiency, reduce grinding cost, and it is considered to be your best

More

The DuraLiner® alumina lining bricks are used as the lining in the ball mill of ceramic industry, cement Industry, paint industry, color industry, chemical industry medicine industry and

More

Multotec provides a range of industrial ceramic linings using efficient production methods, the latest manufacturing equipment and strict quality control. These methods and measurements

More

2024年1月15日 To obtain catalytic porous supports with original properties, including alumina crystallographic phase, textural and acidity properties, the mecanosynthesis was investigated

More

Alumina ball is widely used in industries of ceramics, cements, paint, dyeing, chemicals, pharmaceuticals, coating and mining. It has advantages of high hardness, good toughness,

More

We are specialized in producing and selling alumina grinding products. Main products include alumina ball, alumina lining brick, alumina bead and ceramic roller etc. Our market are Middle

More

2023年1月28日 DBDPM has a higher powder refining efficiency and more unique alloying mechanism than ordinary ball milling due to the temperature detonation effect, electron pulse effect and active group activation effect

More

Services. The services that Rusilex offers to its clients not only consists in relining and repairing the internal lining of mills, but we also have a replace them to optimize loads. COATING

More

Hofmann is supplying wide range of High Alumina Ceramic Liner having size from 30mm to 50 mm thick for ball mill. We also supply liner in standard sizes and pre-engineered wear

More

Main products include alumina ball, alumina lining brick, alumina bead and ceramic roller etc. Our market are Middle East, South Asia and Europe, such as Turkey ... ꄸLearn more ABOUT US. 92% ALUMINA CERAMIC BALL. This product is a grinding body used in ball mill, pot mill, vibrating mill and other fine grinding plants. It ...

More

HJMT ® Medium alumina ceramic lining brick, made mainly by bauxite, after molding, fired at high temperature. Alumina content for the finished brick is about 68%, so it is also called 68% alumina lining brick. Due to its high hardness

More

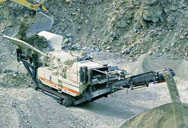

Ball mills are widely used in the mining industry, cement industry, and other industrial sectors. These machines are critical pieces of equipment that grind materials down into fine powders for further processing. Ball mills consist of a rotating cylinder that contains grinding media, such as steel balls or ceramic balls, which grind the material to the desired size.

More

DAGONG MACHINERY, since 1965, is the most professional ceramic machinery manufacturer with a history of more than 50 years. Main products include batch ball mill, continuous ball mill, spray drier, magnetic separator etc. As the biggest ball mill manufacturer, DAGONG is also the only manufacturer producing ball mill by German Robot.

More

2024年8月8日 Unlock the secrets to ball mill efficiency with our comprehensive guide on choosing the right grinding media. Learn how material composition, size, shape, ... AC3939 Alumina Wet Grinding Ball. AC3938 Alumina Dry Grinding Ball. CB4040 Silicon Carbide Bench Grinding Wheel.

More

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

More

UNLOCK PEAK PERFORMANCE WITH FOX ALUMINA BALLS AND CYLINDERS. When steel isn’t an option for your ball mills, FOX Alumina Balls and Cylinders offer the ideal solution. Superior to porcelain, flint pebbles, or

More

2023年7月16日 Mineral liberation from ores is an important step in mineral processing. It is necessary to grind the ore to extremely fine size to liberate the mineral from such ores. The planetary ball mill is promising in that it makes grinding to submicron sizes possible by imparting high energy to the ground powder. In this context, there is a need to understand the dynamics

More

2016年1月1日 The Ball Mill Abrasion (BMA) test was developed by the University of Queensland Materials Performance group to simulate the high stress abrasion conditions experienced in production ball mills.

More

HJMT ® Medium alumina ceramic lining brick, made mainly by bauxite, after molding, fired at high temperature. Alumina content for the finished brick is about 68%, so it is also called 68% alumina lining brick. Due to its high hardness and good impact resistance, acid, alkali, and corrosion resistance, alumina lining brick inlaid in the ball mill, can effectively protect the ball

More

2023年4月19日 The ceramic lining brick of the ball mill, also known as the alumina ceramic lining brick, is a high alumina lining brick that can be used for grinding glaze and ceramic tile embryos.

More

Alumina grinding bricks have high mechanical strength and superb anti-corrosion properties. High alumina lining bricks are also called 92 ceramic lining bricks, ball mill high alumina lining, and microcrystalline wear-resistant high alumina ceramic lining bricks, molded by a two-way hydraulic press and sintered in the high-temperature natural ...

More

2016年10月20日 In the case of ball mills, all internal wearing parts will pass through the manhole, whereas in the case of open end rod mills they will pass through the discharge trunnion opening. When lining the shell, start with the odd shaped pieces around the manhole opening if manholes are furnished.

More

Ball mill liners are essential components in the operation of a ball mill. They play a critical role in the following ways: Protecting the Mill: Ball mill liners protect the mill from wear and tear, reducing the need for repairs and prolonging the lifespan of the mill. Improving Grinding Efficiency: By reducing the amount of friction between the grinding media and the material

More

This product is a grinding body used in ball mill, pot mill, vibrating mill and other fine grinding plants. It hasadvantages of high hardness, ... The microlite alumina wear-resisting lining plateand pieces are dry-compacted and burned with1500C temperature to be special type wear-resistingceramic.

More