2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the

More

Please download the data-file to stress-test mining crushing-grinding costs, across capex, opex, maintenance, labor, electricity prices, CO2 prices, uptime utilization and ore grades. Our 5 conclusions on the crushing-grinding

More

2023年12月8日 The owning costs of a material crusher include the initial purchase price, installation costs, and maintenance costs. The initial purchase price is the most significant owning cost. The size and type of crusher will

More

To fit the generic production cost model to the crushing and screening process a lot of parameters has to be changed and adopted. The major difference is that the original model

More

2022年8月18日 This paper presents a mine-to-crusher model applied to an exceptional mining case study. The objective of this study was to present and calibrate an economic model to calculate and minimize the operating costs for

More

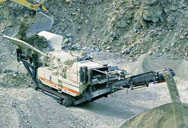

2016年1月11日 Crusher Operating Costs: How to Optimize and Reduce. Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and

More

Whether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process. We are the world’s leading

More

Varioustypes of crusher equipment are required for iron ore crushing, such as jaw crusher, impact crusher, hammer crusher and cone crusher. Iron ore crusher prices are different

More

2023年12月1日 In this paper, the crushing process of spherical iron ore particles in a cone crusher has been numerically reproduced by DEM. The effects of operation parameters

More

2023年12月8日 The crusher is expected to require maintenance costs of $10,000 per year. The crusher is used to crush 100 tons of material per day. The electricity cost is $0.05 per kilowatt-hour, and the labor cost is $10 per hour.

More

Royal Techno India is a trusted manufacturer and supplier of high-quality crushing plants and equipment for various industries. Jaw Crusher, Cone Crusher, VSI-Sand Maker, HSI Impactor. Call now for more information +91 94273 55384,

More

Don't let home maintenance costs crush your budget – The By examining your house and estimating upcoming costs home owners can have a budget to there's something soul-crushing about having to shell out $300 to $500

More

The purpose of this data-file is to tabulate typical cost estimates for crushing-grinding processes, which consume 1-2% of all the energy in the world and 20-50% of the energy in some mining processes. Our numbers are shown per ton of ore, so clearly lower ore grades translate into higher costs per unit of extracted material ().Energy economics.

More

2023年11月20日 Transforming Iron Ore Processing in Nigeria: Cost-Efficient Crushing Plant Setup Nigeria, a nation endowed with vast mineral resources, is at the forefront of a transformative initiative in the ...

More

It is suitable for grinding ore such as iron ore, gold ore, copper ore and lead-zinc ore and other metal beneficiation, used to grind the ore below 0.075mm for subsequent beneficiation process. According to the different discharge methods, it can be

More

2023年12月1日 Due to the decreasing reserves of high-grade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the grade of iron ore through crushing (Gul et al., 2014).The quality of iron ore crushing directly affects the performance of pellets and sinter, so as to influence the quality and performance of

More

Iron ore washing plant in Nigeria, Indonesia and India ... Trommel gold washing plant 200tph – Gold Ore Crusher. About ” trommel gold washing plant 200tph “ Mining equipment for mineral extraction and screening operations equipment, ... A very low-cost wash plants.

More

2022年8月3日 Iron ore is gradually selected through the procedures of crushing, screening, ... From the production efficiency and cost of iron ore, the use of cone crusher can effectively reduce the production cost. ... as well as desliming and

More

2023年7月22日 There are two methods: (1) Fragility coefficient method. The crushability factor is the ratio of the crusher’s ability to crush pending ore and the crusher’s crushing medium-hard ore under the same conditions. Limestone is usually used as the standard medium-hard ore, and its crushability factor is one. (2) Work index method.

More

Crushing Wheels are the more advanced version of the Millstone. It applies Crushing recipes to any items inserted from the direction they are spinning away from. 1) First, arrange the crafter as follows. Note that direction of the arrows

More

iron ore mine cash costs - get-roasted. iron ore mine cash costs. Customer Cases. Iron mining in the United States Wikipedia. Iron mining in the United States produced 42.5 million metric tons of iron ore in 2015, worth US$3.8 billion. Iron ore was the third-highest-value metal mined in the United States, after gold and copper.

More

2016年5月10日 In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy seasons, the crushing plant is a section of the mill which must be planned very carefully. Unless this is done, crushing becomes a constant source of trouble resulting in lost production and high milling cost. In some areas rainfall is high for prolonged periods.

More

In the iron ore crushing production line, in order to improve the production efficiency of iron ore crusher, reduce production costs. Iron ore crushing production line specific process: iron ore by the vibrating feeder evenly sent to the iron ore crusher jaw crusher for coarse crushing, after the material from the tape conveyor into the cone ...

More

Mine rock ore crushing: iron ore, copper ore, gold, lead-zinc, coal ... The equipment provides efficient, low-cost. Usually the jaw crusher can be equipped with a vibrating screen or a belt conveyor to form a small portable crushing plant. It ... Lead Zinc Ore Processing; Chrome Washing Process; Contact Us +86-18879767229 [email ...

More

Iron ore: The size of the particles should be between 120 and 320 mesh. Crushing and milling of iron ore . The iron ore crushing plant is a machine which is used to crush the iron ore into small pieces. The particle size of the iron ore can be controlled by the milling process.

More

2024年10月10日 Factors Influencing the Cost of Mineral Crusher. Several factors influence the total cost of acquiring and operating a mineral crusher: 1. Capacity and Size. Larger crusher with higher capacities will naturally cost more. A jaw crusher with a capacity of 500 tons per hour will be more expensive than one with a 100-ton capacity. 2. Crusher Type

More

tin ore washing machine plant used in india. Jul 21, 2018 Gold washing plant small capacity sand and gravel separator log washer machine Hot selling Iron Ore tin/magnetite/coal log washer plant for mining 2018 new saving yingyong brand sand

More

cost of ultra fine grinder – iron ore crusher, gold ore You want to know why cost of ultra fine grinder Cost of Iron Ore Crushing for mixing ingredients as loose incense but grind everything to an ultra fine powder,

More

2023年9月25日 The cost of iron ore crusher equipment price can vary greatly depending on the type and model of the crusher, as well as the supplier and any additional costs associated with the equipment. Generally, prices for iron ore crushers range from 1,000to1,000 to1,000to10,000 or more, depending on the specific product and capacity.

More